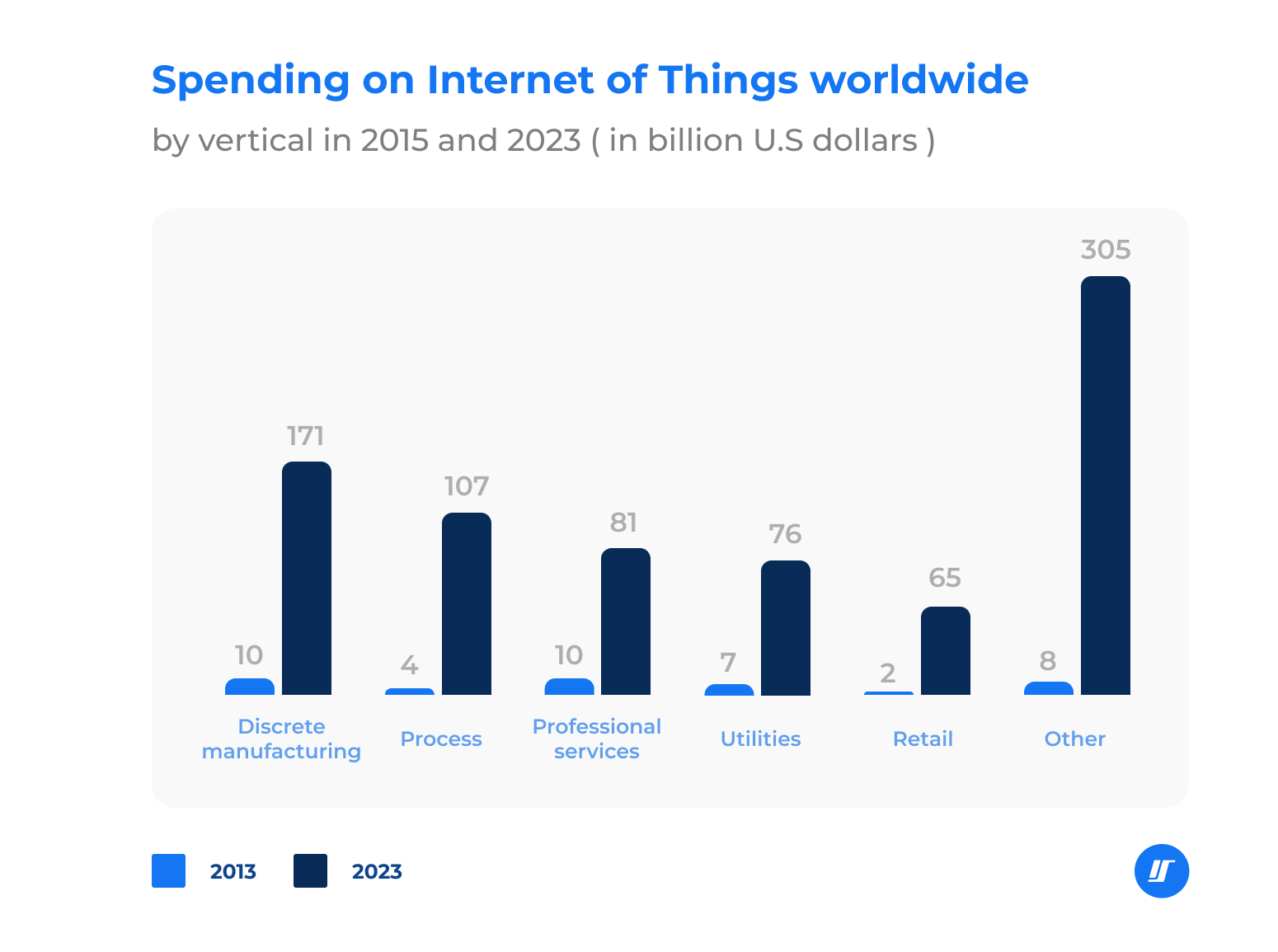

The Internet of Things (IoT) technology brings unmatched benefits of control and connectivity to many industries. The level of such possibilities is immense in comparison to previous technologies, most notably analog and early digital tech, and can be achieved relatively easily. This is the reason why the worldwide investments in IoT skyrocketed over the last decade, and their combined amount now exceeds 800 billion dollars.

Understanding IoT in Supply Chain Management

The Internet of Things refers to the network of smart devices tuned and connected into a comprehensive infrastructure with digital means to record, transmit, store, and analyze data. Without proper connection, the usability of IoT devices is severely limited and they cannot perform the full potential of their functions.

Most commonly, logistics applications use such smart technology as GPS trackers, temperature sensors, accelerometers, imaging devices, and so on. They can collect data regarding environmental conditions during transportation and storage, the route and current position of a truck, and other relevant factors.

To perform and improve the methods of supply chain management and logistics, the IoT infrastructure should include the hardware and software to store, maintain, and analyze the collected raw data. They require significant investments but offer considerable benefits that are well worth their price and ultimately result in cost savings and other optimizations. Let’s take a look at some of the most prominent advantages of IoT technologies in supply chain management.

Key Benefits of IoT in Logistics and Supply Chain Management

The implementation of IoT technology in logistics brings many advantages to different types of businesses. Virtually every stage of the supply chain can benefit from smart technologies and turn them into process optimization and financial profits. Moreover, the advantages of IoT are highly viable for different businesses and even industries that one way or another deal with logistics on a regular basis. Mining companies, storage facilities, delivery companies, and manufacturers of finished goods are just a few examples of such businesses.

Let’s take a look at a few illustrative advantages of implementing IoT technologies in supply chain management and logistics.

Improved Visibility and Transparency of Operations

IoT enables constant tracking and logging that greatly improves the visibility of all logistics-related processes. At every step from the supplier to the customer, the route and state of transported goods are monitored to ensure their proper condition and delivery time.

Smart technologies also improve security by making it much harder for criminals to steal from batches or shipments. In many cases, owners can track stolen goods using GPS data and inform the police about the current location of thieves. For example, Lowe and Home Depot implemented a combination of RFID and blockchain to detect stolen power tools and make them unusable without the proper point-of-sale activation. Other major retailers, such as Walmart and Target, also introduce complex anti-theft solutions that use IoT, AI, and other digital technologies to mitigate and prevent losses due to increasing crime activities.

Improved Utilization of Resources and Assets

The Internet of Things offers logistics managers many possibilities to optimize their storage and transportation resources. Modern industries use various devices that read barcodes, QR codes, RFID tags, and other marks to collect relevant data about goods. This method is especially popular among retailers that have many warehouses in different locations, including such leading enterprises as Amazon and eBay.

IoT also enables further automation with the help of robotics, which leads to reduced workforce and operational costs. Smart devices also allow logistics managers to monitor the location and state of transport vehicles which is helpful for reducing downtime and scheduling maintenance.

Improved Cooperation Between Departments and Branches

The management of logistics and supply chains in large enterprises with a wide network of offices, warehouses, and sales outlets is extremely complex. Luckily, it can be effectively optimized and simplified with the proper digital infrastructure that relies on IoT technologies. All relevant information collected from different smart devices within enterprise property can be transferred for processing and storage in a data center located on-premises or owned by a cloud service provider. This way, data can be easily available to employees at any authorized access point, such as at any office, store, or warehouse.

Improved Collaboration with Suppliers and Distributors

Data from GPS trackers installed in transport vehicles can also be shared with the relevant partners. This way, the logistics company can inform them about the location of vehicles that are supposed to pick up or deliver shipments. The improved automation and control provided by IoT technologies greatly streamline cooperation by making operations transparent and predictable. This is especially useful in relations between transport companies and retailers or between suppliers and producers, for example, between a mining company and a refining factory or between a farming company and a food processing plant.

Improved Working Conditions and Compliance

The use of IoT in supply chain management reduces human involvement by relieving workers from tedious routine activities. The extensive use of automation combined with AI and robotics also takes over the most dangerous and heavy-duty tasks, including loading and unloading, sorting, and so on.

Moreover, enhanced control resulting from the implementation of IoT can ensure the company’s compliance with applicable regulations regarding the safety and security of goods, workforce, and other assets. This advantage is especially useful when a company deals with products and materials that are subject to specific legislation, such as hazardous chemicals, food products, pharmaceuticals, and others.

Additionally, IoT technologies are widely used in logistics and retail industries to monitor and control environmental conditions in storage facilities and transport vehicles. Most often, smart devices are configured to measure and maintain temperature and humidity within predefined ranges to avoid spoiling of perishable products. As one example, Maersk, which is one of the global leaders in the logistics industry, is known for its effective implementation of IoT in the company’s warehouses and shipping containers.

Improved User Experience

Transparency and predictability of logistics operations provided by the Internet of Things also appeal to customers of retailers and delivery companies. The ability to track a parcel and know the time of delivery has become a convenient standard for most international and local companies that send products to individuals. Barcode scanners identify shipments automatically and GPS trackers send relevant data to consignees periodically or in real time. For example, parcel-related information is usually shown to respective authorized users in a mobile application or on the website of the respective store or delivery company.

Improved Business Planning

Numerous benefits of IoT in logistics and other industries enable new possibilities for the optimization of existing methods and devising new strategies. Information obtained from smart devices can be analyzed by human experts and AI to detect flaws, prevent accidents, improve workflow, and ensure uninterrupted operation. The comprehensive analysis of structured data may reveal new business opportunities and ways to improve existing strategies.

These days, most logistics companies are actively implementing “green” standards by reducing emissions and waste that are commonly associated with transport vehicles. As one example, the combination of IoT, AI, and Big Data can be used to correlate GPS data from trucks with local traffic and weather information to optimize delivery routes depending on the season and time of day. As a result, a logistics company can reduce transportation and maintenance costs and build a positive reputation as an environmentally friendly business at the same time.

IoT Applications in Supply Chain

Considering the range and potency of benefits described above, many aspects of the logistics routine can be greatly enhanced using IoT devices. Let’s take a look at some processes involved in supply chain and logistics that make an effective use of smart devices.

Shipment and Delivery Tracking

The use of geolocation services has proven its overwhelming effectiveness in monitoring the transportation of goods and raw materials. These days, a small GPS tracker is a reliable and accurate source of real-time location data which allows business owners to know the whereabouts of their trucks, products, and raw materials. Thanks to IoT technologies, customers can easily track their parcels and see the estimated delivery date and time of their purchased goods.

Warehouse Capacity Monitoring

IoT technologies improve the management of storage facilities by tracking the occupied and available capacities. This is especially useful in the case of the intense flow of incoming and outgoing freight. For example, logistics managers can know in advance whether a warehouse will be able to accept incoming cargo and what storage volume becomes available every time shipments are loaded in trucks.

Inventory Management

In addition to tracking storage capacity, IoT technologies greatly simplify the monitoring and audit of the current inventory. For a retail company, this involves determining what goods are out of stock and what range of commodities are available at the moment. In this case, such information can be reflected in the online shop of the retailer, so that customers who browse goods using a mobile application or a website can see the current stock. This information is constantly updated thanks to the well-designed infrastructure of smart devices functionally connected to data storage and processing means. Through this intricate network, information obtained, for example, from barcode scanners and RFID tags is transformed and relayed to a shopping app.

Storage Conditions Monitoring

Most products and raw materials require maintaining a specific environment for storage and transportation. If proper conditions are not met, the goods could spoil, become damaged, or lose their marketable appearance. Raw materials could degrade in quality, change their

chemical composition, and lose specific properties, making them useless in processing and manufacturing. To prevent such disastrous effects, many industries employ monitoring systems that include sensors and meters capable of measuring temperature, humidity, pressure, light intensity, and other environmental conditions. If any measurement falls outside the predetermined thresholds, the relevant product or material should be inspected to reevaluate its quality.

Routine Optimization and Automation

Many other operations that require human involvement and a “pen-and-paper” approach can be streamlined with digital technologies. The Internet of Things promotes automation and reduces the need for human operators to perform routine repetitive tasks. The combination of IoT with other digital technologies, for example, AI and ML can further increase the possibilities of automation and create new ways of supply chain optimization. Moreover, such a combination allows engineers to develop new business strategies, minimize accidents, and perform other improvements.

Challenges and Solutions in the Supply Chain and Logistics Industry

These days, it becomes increasingly difficult to run a profitable supply chain and logistics business. Let’s review several challenges that are common in this industry and see how they can be mitigated using IoT technologies.

Ineffective Business Processes

Business strategies require constant optimization and modernization which demand research and investments. Changes in the global economy and local markets directly impact the profitability of existing schemes and methods. IoT provides valuable information to analyze and find ways to improve business processes, create new strategies, and discontinue ineffective approaches.

Increasing Costs of Transportation

Oil shortage, rising gas prices, and growing traffic in popular areas increase the costs of transportation, making most businesses less profitable. Since most industries rely on transportation services in one way or another, the said increase creates a chain reaction of growing prices in many other fields. That’s why analysts and engineers use IoT to optimize routes and find new effective ways to deliver products and raw materials.

Environmental Impact

Environmental awareness has changed from a fancy trend to an absolute necessity for any company that wants to build a good reputation on the market. Optimization and monitoring provided by IoT help businesses turn green by cutting emissions and reducing waste. Trucks, vans, and other vehicles commonly used in logistics are notorious for being gas guzzlers. That’s why any optimization in supply chain management would be beneficial for both business and the environment.

Growing Customer Expectations

Technological progress spoils customers by making them demand better services at lower prices. These days, businesses must indulge these expectations in order to retain their existing client base and attract new customers. IoT helps logistics companies reduce delivery time, ensure shipment safety, and share required information with customers using mobile devices or other convenient means of communication.

Regulatory Compliance

Transportation and storage of many materials and goods are strictly regulated by various standards and laws. Luckily, IoT provides sufficient control, monitoring, and security to comply with such regulations. Smart devices ensure video surveillance, location tracking, authenticity verification, and other means to keep deliveries safe.

IoT Implementation Strategies

Similar to other digital technologies, the implementation of IoT requires a lot of planning, investments, and customizations. It’s not enough to simply buy and install smart devices to use them effectively for business optimization and other benefits. Here are a few essential steps of IoT integration:

- Evaluate the scale and needs of your business.

- Plan the “smart” infrastructure that solves your needs.

- Create and configure a data center to process and store information.

- Acquire, install, and connect smart devices, such as cameras, trackers, routers, etc.

- Prepare and configure software that ensures proper functioning of hardware and transfer of data.

- Process information into a structured form for further analysis.

This is the most basic strategy that must be refined and customized for each specific business and its requirements.

Future Trends in IoT and Logistics

One of the most promising future trends in logistics is the 100% automation of most processes. From self-driving delivery trucks to loading robots, IoT will soon turn many of these sci-fi concepts into our everyday reality.

Another interesting trend is the shift from gas-fueled delivery vehicles to electric cars and even drones. Amazon already uses drones to deliver parcels in specific areas in California and Texas. It is safe to assume that other businesses will eventually copy this initiative and find ways to remove current technological limitations and further improve logistics efficiency.

The global coverage of 5G and other network technologies is growing every day, resulting in better connectivity for smart devices. With the development of satellite Internet services, as shown by Starlink, the benefits of IoT will be more accessible even for the most remote corners of the world.

Final Thoughts

The Internet of Things has already brought many advantages to the supply chain and logistics, as well as many other industries. With all the information stated in this article, one can reach a conclusion – the longer you delay the implementation of IoT in your supply chain business processes, the harder it will get for your business to succeed on the market in the near future.

In case you’re looking for a reliable company with solid experience in providing IoT solutions for supply chain management and logistics, we suggest you consider hiring the Intellectsoft team. Just like implementing the Internet of Things in your processes, working with Intellectsoft has many perks. Here are only a few benefits of choosing us to create custom solutions for your business:

- We use a wide range of programming tools and technologies for creating mobile, web, cloud, desktop, and other solutions.

- We provide top-quality solutions for businesses of all sizes – from startups to Fortune 500 enterprises like Nestle, Mitsubishi, Intel, Melco, Harley-Davidson, and others.

- Over 15 years, we have delivered 600+ bespoke digital solutions for our clients.

- We have an engineering workforce in 21 countries.

So, if you want to empower your supply chain and logistics business with IoT solutions, get in touch with us right away to leave your competitors far behind.

FAQ

What role does IoT play in supply chain optimization?

IoT is essential for effective supply chain and logistics management. Besides ensuring control and security, smart devices provide valuable data that can be analyzed to optimize various business processes.

Are there security concerns of using IoT in supply chain and logistics?

Smart devices require a constant network connection and reliable electricity sources. These features are potential vulnerabilities of the Internet of Things. When IoT devices are disconnected from their infrastructure, their functionality becomes severely compromised. Also, smart devices also become the targets of hacker attacks and serve as potential points of unauthorized access to enterprise intranets.